PVA sponge roller is an indispensable material in the manufacturing process of PCB machine, and its unique absorbent and liquid absorbent properties play an important role in the field of electronic manufacturing. As a highly absorbent material, absorbent quilts are widely used to clean, dry and maintain the working environment of equipment, thereby improving production efficiency and ensuring product quality.

According to the different use of the environment, in addition to PVA sponge, there are PU sponge roller, PVC sponge roller, PP sponge roller, PO sponge roller, EPDM sponge roller and brush materials to choose from, the following is the introduction of different materials of sponge roller, as well as their advantages and disadvantages and the difference between the use of the environment.

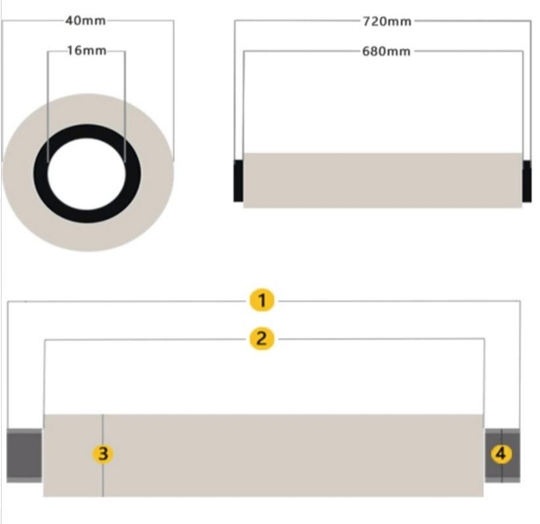

Product introduction:

Sponges have good elasticity, water absorption rate of 8-10 times (self weight), do not open glue, do not drop slag, solvent resistance and weak acid and alkali can be good, white and soft appearance, after special anti-mildew treatment, will not mold within 6 months.

Product Feature:

Our PVA sponge roller technology, process and management model are all from Taiwan, and the main raw material of PVA is imported from Japan and Taiwan. Its characteristics include strong toughness, resistance to friction and not easy to drop chips.

Product Note:

No moisture PVA sponge is dry and hard. Soak the foam roller in water for more than 2 hours before use, and squeeze the foam roller internal hard block completely, squeeze out too much water and then install it on the machine (do not put the dry and hard PVA sponge roller directly on the machine).

Product Data Sheet:

Physical Features | |

Specific Gravity | 0.1~0.15%/cm³ |

Pore Ratio | 90% |

Water-retention Ratio | 13 Times |

Hole Size | 60~130μ |

Stretchability | 4kg/c㎡ |

Extensibility | 300% |

Product introduction:

The PU sponge roller is made from polyurethane and utilizes advanced Japanese continuous ultra-fine foaming technology.

Product Feature:

The material exhibits strong water absorption, is resistant to cracking, demonstrates excellent durability against abrasion, and does not shed particles.

Product Note:

Suitable for specialized cleaning sponges for semiconductor wafers.

Product Data Sheet:

Physical Features | |

Pore Diameter | 5~10μ |

Pore Ratio | 80% |

Water-retention Ratio | 300% |

Specific Gravity | 0.26/cm³ |

Max temperature | 120℃ |

Stretchability | 13.0kg/cm³ |

Ductility | 400% |

Hardness | 10° |

Product introduction:

PVC sponge roller adopts advanced ultrafine continuous foaming technique in Japan, which is not easy to drop chips, has high tensile strength and is not easy to deform. Good drug resistance, for general organic solvents have chemical resistance, long-term exposure to acid and alkali solution is not easy to change.

Product Feature:

With high foaming density and continuous foaming technology, it has excellent acid and alkali resistance and durability. In the dry state can maintain elasticity and softness, and not dry hard, no need to add water moisturizing.

Product Note:

The outer diameter error of the PVC sponge roller is 5% of the soil, more than 10 days of impregnation in water, there will be 10% expansion error of the soil, and the above test is 10 days of external roundness and elasticity.

Product Data Sheet:

Physical Features | |

Specific Gravity | 0.35~0.37g/cm³ |

Pore Ratio | 73%-75% |

Water-retention Ratio | 280% |

Hole Size | 2~50μ |

Temperature | 60℃ |

Extensibility | 125~131% |

Product introduction:

PO sponge roller adopts Japan’s advanced ultrafine continuous foaming process. Polyurethane is used as raw material. Mainly used in circuit board, inner board, liquid crystal display and etc.

Product Feature:

Corrosion resistance, no hardening, drug resistance, hydrophilicity.

Product Note:

After use, use a container (kettle) to pour tap water on the PO roller on the machine, and then squeeze the dirt on the PO sponge roller by hand. The roller does not need special water supply, will not dry in the state of no water, and will always maintain the roundness and elasticity of the roller appearance.

Product Data Sheet:

Physical Features | |

Pore Diameter | 60μ |

Pore Ratio | 75% |

Max temperature | 70℃ |

Tensile strength | 420 |

Ductility | 200% |

Hardness | 15° |

Product introduction:

A new product specially developed for the chemical extrusion fluid of base plate. Using polyethylene as a chemical bridge, improved polymer structure of the micro foam.

Product Feature:

Heat resistance, alkali resistance, wear resistance, acid resistance.

Product Note:

When not in use, it should be often maintained in clean water to avoid deformation. The use environment should not exceed 80°C, which will shorten the use period. Daily squeeze cleaning with water can increase the service life of the sponge roller and maintain the roundness and elasticity of the roller.

Product Data Sheet:

Physical Features | |

Specific Gravity | 0.031g/cm³ |

Tensile strength | 1.6kg/c㎡ |

Ductility | 220% |

Max temperature | 60℃ |

Compression ratio | 7.8% |

Product introduction:

Vertical plating line accessories can play a role in water retention.

Product Feature:

Acid and alkali resistance, corrosion resistance, good elasticity, no damage to the board durable. Customized according to user needs.

Product Note:

When not in use, it should be often maintained in clean water to avoid deformation. The use environment should not exceed 80°C, which will shorten the use period. Daily squeeze cleaning with water can increase the service life of the sponge roller and maintain the roundness and elasticity of the roller.

Product Data Sheet:

Physical Features | |

Specific Gravity | 0.033g/cm³ |

Tensile strength | 1.8kg/c㎡ |

Ductility | 220% |

Max temperature | 65℃ |

Compression ratio | 7.5% |

Filtration capacity:

The maximum processing flow of the filter (in cubic meters per hour or gallons per minute), which needs to match the flow of the pump.

Filtration accuracy (such as micron grade), according to the actual filtration needs to choose the appropriate accuracy.

Interface size: Confirm the diameter of the inlet and outlet pipe (such as DN25, DN50, etc.) to ensure compatibility with the pipe system.

Working pressure and pressure resistance: the rated working pressure and maximum pressure resistance value of the filter (unit: bar or PASCAL), which must conform to the working pressure range of the system.

Material: Select filter material (such as stainless steel, PP, PVC, etc.) according to the chemical properties of the medium (such as acid and alkali, temperature).

Type of filter media: Identify the type of filter media to be used (e.g., filter element, filter bag, sand filter, activated carbon, etc.) and the convenience and cost of replacement.

Use environment: operating temperature range, and whether it is suitable for specific occasions (such as anti-corrosion, explosion-proof, etc.).

We’re professional manufacturer of PCB equipment and consumable. We can give you the best advice for your requirements.

© All Rights Reserved.

WhatsApp us

Eternal Tech is committed to becoming an expert in PCB conveying systems.