More than 3000 square meters of warehouse, with a large stock

Light weight, small size, easy to air delivery

Injection molding department and machining department

24/7 one-on-one engineer service support

In circuit board (PCB) equipment, the Magnetic Wheel is usually a device component used for the transmission and processing of printed circuit board (PCB) materials. It plays a very important role in automated production lines, especially in the processing and assembly of PCBS.

Introduction: Stainless steel magnetic wheel is a commonly used component in circuit board equipment, especially in the automated production line and PCB (printed circuit board) manufacturing process, plays an important role. Its main function is to use the magnetic principle to provide a stable physical force to help automated equipment carry out parts handling, positioning, control and other operations.

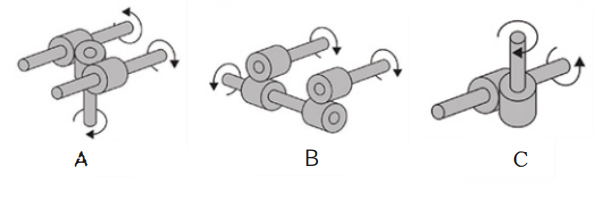

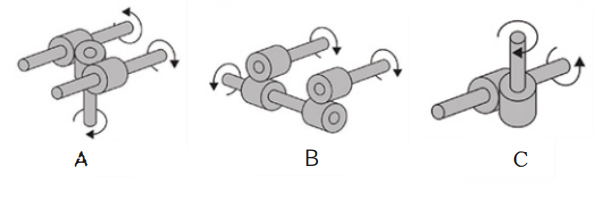

Occlusal pattern:

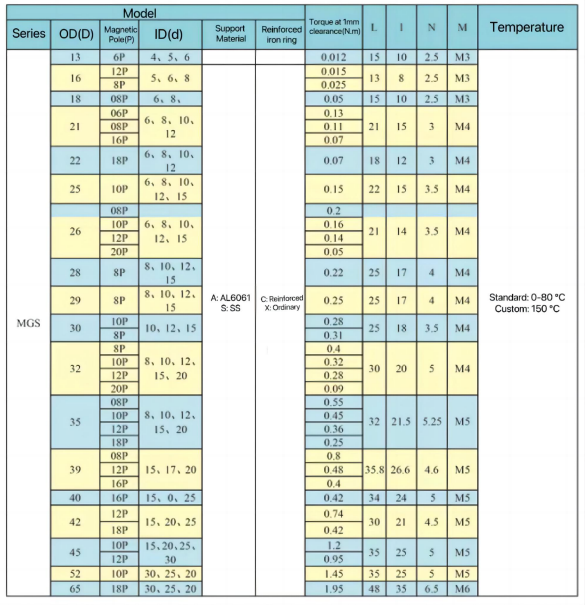

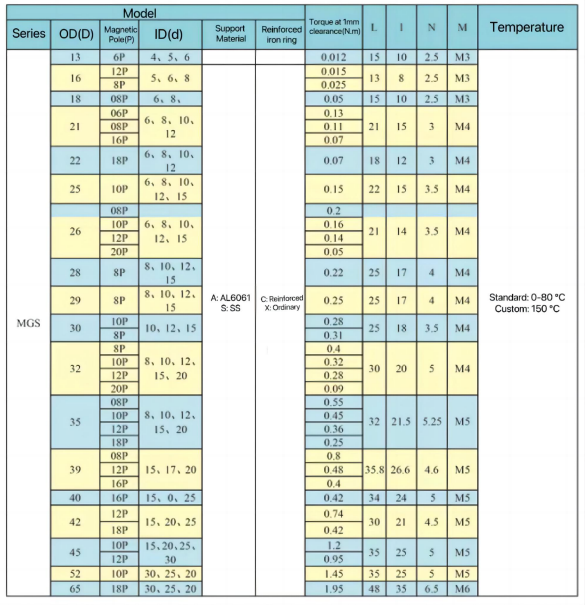

Data Sheet:

Advantage:

Frictionless drive: Because the magnetic drive is non-contact, it reduces mechanical friction and reduces wear and energy loss.

Low noise: The traditional mechanical gear is easy to produce noise due to friction when meshing, and the magnetic transmission of aluminum magnetic gear can greatly reduce noise.

Efficient transmission: The efficiency of the magnetic drive system is higher, especially at high speed to maintain a high transmission efficiency.

Precision control: Due to the light weight and low inertia of the aluminum material itself, with the precision control of the magnetic drive, it can provide accurate rotation control.

Corrosion resistance: Aluminum alloy has strong corrosion resistance, which makes the magnetic gear adapt to the harsher working environment and extend the service life.

Introduction: Aluminum Magnetic Gear (Aluminum Magnetic Gear) is a combination of aluminum materials and magnetic drive technology gear system, commonly used in applications requiring high performance, high precision, low noise and low friction. In the field of precision machinery such as circuit board equipment, aluminum magnetic gears are commonly found in motor drives, precision transmissions and deceleration systems.

Occlusal pattern:

Data Sheet:

Advantage:

Frictionless drive: Because the magnetic drive is non-contact, it reduces mechanical friction and reduces wear and energy loss.

Low noise: The traditional mechanical gear is easy to produce noise due to friction when meshing, and the magnetic transmission of aluminum magnetic gear can greatly reduce noise.

Efficient transmission: The efficiency of the magnetic drive system is higher, especially at high speed to maintain a high transmission efficiency.

Precision control: Due to the light weight and low inertia of the aluminum material itself, with the precision control of the magnetic drive, it can provide accurate rotation control.

Corrosion resistance: Aluminum alloy has strong corrosion resistance, which makes the magnetic gear adapt to the harsher working environment and extend the service life.

102, No.14-1 Jixiang 3rd Road, Yixin Community, Longgang District, Shenzhen, Guangdong Province, China.

+ 86 181 8840 4906

eternal02023@gmail.com

We’re professional manufacturer of PCB equipment and consumable. We can give you the best advice for your requirements.

© All Rights Reserved.

WhatsApp us

Eternal Tech is committed to becoming an expert in PCB conveying systems.