More than 3000 square meters of warehouse, with a large stock

Light weight, small size, easy to air delivery

Injection molding department and machining department

24/7 one-on-one engineer service support

Chemical Etching Machine for PCBs (Printed Circuit Boards) is a crucial tool used in the manufacturing process of PCBs. This equipment employs chemical solutions to remove unwanted copper from a copper-clad laminate, creating the desired circuit patterns on the board.

Etching Tank of chemical etching machine: The etching tank is the primary vessel used to hold the chemical solution that etches away the unwanted copper from the PCB. The tank is typically made of materials that are resistant to the corrosive chemicals used in the etching process. This component holds the etching solution (usually ferric chloride or ammonium persulfate) and submerges the PCB for the etching process.

Spray System of chemical etching machine: A spray system is used to apply the etching solution onto the PCB, ensuring uniform coverage across the surface. This system helps maintain an even etch by spraying the chemical solution at high pressure, which speeds up the etching process and reduces the chance of uneven etching.

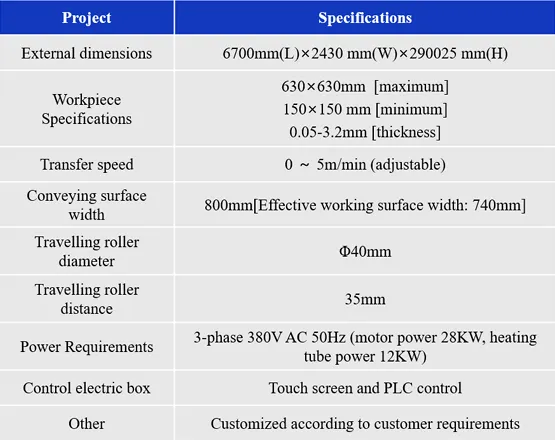

Conveyor System of chemical etching machine: The conveyor system moves the PCB through the etching process in a continuous or semi-continuous manner. It ensures the PCB is properly submerged in the etching solution, or sprayed uniformly, while also moving it to the rinsing or drying section after etching.

Rinse Section of chemical etching machine: After the etching process, the PCB needs to be rinsed to remove any residual etching chemicals. The rinse section ensures that the PCB is thoroughly cleaned before further processing, preventing contamination in subsequent stages.

Drying System of chemical etching machine: A drying system, such as a hot air blower or a drying oven, is used to remove any remaining moisture from the PCB after rinsing. Drying the PCB ensures no water or chemical residue remains, which could affect the quality of the final product.

Chemical Filtration and Recirculation System: This system is used to filter and recirculate the etching chemicals in order to maintain the proper concentration and extend the life of the chemicals. It filters out debris and contaminants from the etching solution and ensures that the etching process remains efficient and consistent.

Control Panel of chemical etching machine: The control panel allows operators to monitor and control various aspects of the etching process, including temperature, chemical flow rate, conveyor speed, and spray pressure. It provides precise control over the etching process, ensuring high-quality results and minimizing errors.

Ventilation System of chemical etching machine: A ventilation system is necessary to remove any toxic fumes generated by the etching chemicals. It ensures a safe working environment by extracting harmful vapors, especially during the heating or spray stages.

Etching Solution Heater: Some chemical etching systems use a heater to maintain the temperature of the etching solution within an optimal range. Heating the solution helps to accelerate the etching reaction, leading to faster and more efficient processing.

Pre-treatment/Preparation: Before etching, the PCB is cleaned to remove any impurities or contaminants that might interfere with the etching process. This is often done using a combination of ultrasonic cleaning and chemical baths. The surface of the copper is typically coated with a resist material, which will protect certain areas during the etching process.

Exposure to Light: The PCB is exposed to ultraviolet (UV) light through a photomask, which is a stencil containing the design of the circuit. The resist material hardens in areas exposed to the UV light, while areas that are not exposed to light remain soft. After exposure, the board is developed, and the unexposed resist is washed away, leaving only the hardened resist in place.

Chemical Etching: The board is then submerged in an etching solution, typically a mixture of chemicals like ferric chloride, copper chloride, or ammonium persulfate. The etching solution dissolves the copper that is not protected by the resist, leaving behind the desired circuit pattern. The etching process can be performed in several ways, including:

Spray etching: The etchant is sprayed onto the surface of the board.

Immersion etching: The entire board is submerged in a bath of etchant.

Roller etching: The board is passed through rollers that apply the etching solution.

Post-Etching Treatment: After the etching process is complete, the board is thoroughly rinsed to remove any residual chemicals. The remaining resist material is then removed, usually using a solvent or alkaline solution.

Inspection and Quality Control: The etched PCB is inspected for defects such as under-etching or over-etching. Quality control steps are crucial to ensure the final product meets the design specifications and electrical requirements.

Equipment Used in Chemical Etching:

Etching Tank: A tank to hold the etching solution (either spray, immersion, or roller-based).

UV Exposure Unit: Used to expose the photoresist layer to UV light for patterning.

Developing System: After UV exposure, the board is developed to remove the unexposed resist.

Cleaning System: Used to clean the board before and after etching, often incorporating ultrasonic or chemical cleaners.

Rinsing System: After etching, a rinse system is used to wash off residual etching chemicals.

Uneven etching, where the etching process is inconsistent across the PCB surface, can lead to defects in the final product. This could result in areas that are either under-etched or over-etched.

Solutions: Regularly monitor and maintain proper etchant concentration and temperature. Ensure the etchant is circulating evenly to maintain uniform etching. Adjust exposure time to match the material and etching requirements. Position PCBs consistently during the etching process to avoid uneven results.

Excessive etching leads to the removal of too much copper, damaging the PCB’s conductive paths and possibly causing electrical failure.

Solutions: Monitor and adjust the exposure time to prevent over-etching. Control the etchant temperature to ensure it remains within the recommended range. Regularly check and maintain the proper etchant concentration.

Under-etching means that some copper remains on the board, causing unwanted connections or poor electrical performance.

Solutions: Ensure the PCB is fully exposed to the etchant solution for the appropriate time. Replace contaminated or depleted etching solutions regularly. Maintain the etchant temperature within the specified range for optimal performance.

Residual etching solution or copper particles left on the PCB can affect the quality of subsequent processes, such as soldering or coating.

Solutions: Thoroughly rinse PCBs after etching to remove all etchant residues. Use clean, filtered water for the rinse process to prevent contamination. Implement automated cleaning systems to ensure consistent results.

Dirty or contaminated etching equipment can lead to poor etching results or even damage the PCB material.

Solutions: Regularly clean etching tanks, pumps, and nozzles to prevent the build-up of residue. Schedule periodic maintenance to check for any malfunctioning components. Use high-quality etching chemicals to minimize contamination.

As the etching solution ages, its effectiveness diminishes, leading to poor etching quality or inconsistent results.

Solutions: Regularly replace or replenish the etching solution to maintain its strength and consistency. Store etching chemicals in a controlled environment to minimize exposure to air and light.

102, No.14-1 Jixiang 3rd Road, Yixin Community, Longgang District, Shenzhen, Guangdong Province, China.

+ 86 181 8840 4906

eternal02023@gmail.com

We’re professional manufacturer of PCB equipment and consumable. We can give you the best advice for your requirements.

© All Rights Reserved.

WhatsApp us

Eternal Tech is committed to becoming an expert in PCB conveying systems.