More than 3000 square meters of warehouse, with a large stock

Light weight, small size, easy to air delivery

Injection molding department and machining department

24/7 one-on-one engineer service support

PCB manufacturing machine refers to a range of specialized equipment used in the production of Printed Circuit Boards (PCBs), which are essential components in virtually all electronic devices. These machines automate various processes involved in PCB fabrication, such as drilling, etching, plating, testing, and assembly. Each machine is designed to perform a specific task, and they work together in a production line to transform raw materials into functional circuit boards that will house electronic components.

Loader & Unloader of PCB Manufacturing Machine: Transfers PCBs in and out of the production line automatically.

Common Equipment: PCB Loader, PCB Unloader, Magazine Loader.

Printing System of PCB Manufacturing Machine: Applies solder paste or conductive ink onto the PCB surface.

Common Equipment: Solder Paste Printer, Screen Printer.

Pick and Place Machine of PCB Manufacturing Machine: Automatically places electronic components onto the PCB with high precision.

Common Equipment: SMT Pick and Place Machine, Chip Mounter.

Reflow Oven of PCB Manufacturing Machine: Heats the PCB to melt and solidify the solder, ensuring strong electrical connections.

Common Equipment: Infrared Reflow Oven, Convection Reflow Oven.

AOI (Automated Optical Inspection) System of PCB Manufacturing Machine: Inspects PCB for soldering defects, misaligned components, and missing parts.

Common Equipment: AOI Machine.

Wave Soldering Machine of PCB Manufacturing Machine: Soldering through-hole components by passing the PCB over a wave of molten solder.

Common Equipment: Lead-Free Wave Soldering Machine.

X-ray Inspection System of PCB Manufacturing Machine: Examines hidden solder joints, especially in BGA and CSP components.

Common Equipment: X-ray Inspection Machine.

Depaneling Machine of PCB Manufacturing Machine: Separates multiple PCBs from a single panel after assembly.

Common Equipment: PCB Router, PCB V-Cut Machine.

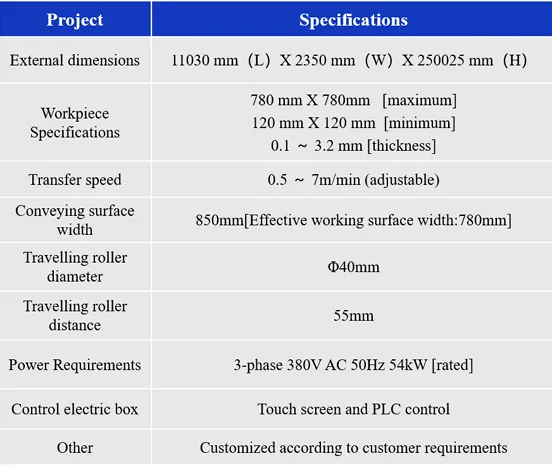

Conveyor System of PCB Manufacturing Machine: Transports PCBs between different machines in the production line.

Common Equipment: PCB Conveyor Belt.

Cleaning System of PCB Manufacturing Machine: Removes flux residues, dust, and other contaminants from the PCB.

Common Equipment: Ultrasonic PCB Cleaner, PCB Cleaning Machine.

Design & Pre-Production: The PCB design is created using Electronic Design Automation (EDA) software. Design files (Gerber files) are reviewed and checked for errors. A panelization process is performed to optimize manufacturing efficiency.

Material Preparation & Cutting: Raw PCB material, typically FR4 (fiberglass-reinforced epoxy), is cut into required panel sizes.

Inner Layer Imaging & Etching (For Multilayer PCBs): A photosensitive dry film is applied to the inner layers. UV light exposure and chemical development define the circuit pattern. Unwanted copper is etched away, leaving the circuit traces intact.

Layer Alignment & Lamination: Multiple layers are aligned using optical registration systems. The layers are laminated under high temperature and pressure to form a solid PCB stack-up.

Drilling: CNC drilling machines create vias and through-holes according to the design specifications.

Plating & Copper Deposition: Electroless copper plating is applied to the drilled holes to ensure electrical conductivity. Additional copper plating may be performed using electroplating techniques.

Outer Layer Imaging & Etching: A dry film resist is applied to the outer layers. The circuit pattern is exposed, developed, and etched to form copper traces.

Solder Mask Application: A protective solder mask layer is applied to insulate the copper traces and prevent solder bridging.

Surface Finish: Different surface finishes, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative), are applied for solderability and oxidation protection.

Silkscreen Printing: Component labels, logos, and reference markings are printed onto the PCB.

Electrical Testing & Quality Control: Automated optical inspection (AOI) and flying probe tests ensure there are no defects. High-voltage tests check for shorts and opens in the circuit.

Profiling & Cutting: The PCBs are cut into their final shape using routing or V-cut processes.

Final Inspection & Packaging: A final visual inspection is performed. PCBs are packaged and prepared for shipment.

Solution: Increase etching time or concentration of etchant. Ensure uniform spray pressure and proper nozzle alignment. Regularly clean and replace etchant solution.

Solution: Reduce etching time or concentration. Improve resist adhesion and ensure even resist coating. Monitor temperature and chemical balance in the etching tank.

Solution: Ensure proper cleaning and surface preparation before plating. Maintain correct plating bath temperature and chemical composition. Increase agitation to improve chemical circulation.

Solution: Adjust current density and plating time. Check for contamination in the plating bath. Regularly clean anodes and cathodes to ensure uniform deposition.

Solution: Use high-quality photoresist and maintain even coating thickness. Ensure exposure unit is clean and properly aligned. Regularly replace UV lamps and adjust exposure time.

Solution: Improve cleaning process before resist application. Optimize baking temperature and drying time. Check for proper lamination pressure and speed.

Solution: Ensure thorough PCB surface cleaning before applying solder mask. Optimize curing time and temperature. Use high-quality solder mask ink.

Solution: Adjust printing pressure and screen alignment. Use high-resolution printing screens. Dry the PCB properly before applying silkscreen.

Machine Accuracy & Precision

Ensure the machine provides high precision, especially for drilling, etching, and placement of components. Look for specifications such as tolerance levels, resolution, and alignment accuracy.

Production Capacity & Speed

Evaluate the machine’s processing speed and its ability to handle high-volume production.

Consider if the machine supports batch or continuous production.

Ensure it can meet your current and future production demands.

Compatibility with PCB Types

Check if the machine supports different PCB types:

Single-layer, double-layer, or multi-layer PCBs

Flexible (FPC) and rigid-flex PCBs

High-frequency or metal-core PCBs

Ensure compatibility with various PCB sizes and thicknesses.

Software & Automation Features

Look for user-friendly software with a good interface for easy operation.

Ensure it supports CAD, Gerber files, and other industry-standard formats.

Consider automation features like:

Auto calibration

Real-time monitoring & error detection

AI-based defect analysis

Reliability & Maintenance Requirements

Choose a machine with robust build quality for long-term durability.

Check the maintenance schedule, spare parts availability, and service support.

Machines with self-diagnostic and easy troubleshooting features are preferable.

Energy Consumption & Environmental Impact

Assess the power consumption of the machine to ensure energy efficiency.

Check if it complies with environmental standards (RoHS, REACH) for waste disposal and emissions.

Cost & Return on Investment (ROI)

Compare the initial cost, operating costs, and long-term ROI.

Look for a balance between cost and performance.

Consider leasing options or financing plans if available.

Supplier Reputation & After-Sales Support

Choose a trusted brand or supplier with good customer feedback.

Check for warranty, training, and technical support availability.

Ensure they provide spare parts and machine upgrades.

Customization & Scalability

Some machines allow custom modifications based on specific manufacturing needs.

If your business is expanding, ensure the machine can scale with future production growth.

102, No.14-1 Jixiang 3rd Road, Yixin Community, Longgang District, Shenzhen, Guangdong Province, China.

+ 86 181 8840 4906

eternal02023@gmail.com

We’re professional manufacturer of PCB equipment and consumable. We can give you the best advice for your requirements.

© All Rights Reserved.

WhatsApp us

Eternal Tech is committed to becoming an expert in PCB conveying systems.